The basic concepts of Asset Performance Management (APM) have been around for nearly fifty years. In the 1960s, plant maintenance departments understood that doing preventative or scheduled maintenance led to better results than simple break-fix approaches. I know this because that's when I started my career in plant engineering.

Admittedly, it was done with large paper tub files then and it wasn’t until the 1970s that we started to see the computerization of maintenance activities, which enabled further advances such as predictive maintenance. And then in the last several decades further advances in maintenance philosophy like condition-based maintenance (CBM) and reliability-centered maintenance (RCM) emerged.

In this post, we'll discuss the wealth of knowledge on different maintenance approaches available to today's professionals, and also the main challenges with putting those approaches into action.

Performance-Oriented Maintenance Approaches Are Well-Documented

Advanced maintenance practices ranging from simple preventative maintenance to RCM all have literally hundreds of guides and how-to articles, as well as benefits and justification articles written about them.

A quick search of Amazon with the phrase “preventative maintenance” will yield over 500 hardback and paperback results. A similar search for RCM yields over 50 books. Google searches on the same topics yield over 500,000 hits each. Scholarly articles on the topics number in the hundreds.

Various surveys have shown that fewer than 20% of manufacturing plants today are not using some form of predictive maintenance strategy. Numerous case studies document the benefits of adopting advanced asset performance management approaches, with cited benefits including 5-20% reductions in maintenance costs, 15% or more improvements in product quality, up to 10% reductions in downtime, and others.

Organizations like the Society for Maintenance & Reliability Professionals (SMRP) exist to support the profession with conferences, certification programs, and a library of resources.

Why is There So Much Interest in Improving Asset Performance?

Despite all that exists in the web sphere about improving asset performance, it still remains one of the most elusive areas when it comes to actually achieving documented benefits. While more than 75% of enterprises report practicing some level of predictive maintenance and about 20% claim to be utilizing RCM, the topic still drives considerable inquiry as to how to actually make it work.

Being from St. Louis, I'm reminded of a famous Yogi Berra quote. When asked why he no longer visited Ruggeri’s Italian restaurant, a St. Louis institution, Yogi replied, “Nobody goes there anymore, it’s too crowded.” In some ways that describes the struggles many companies have in trying to extract maximum value from their assets in an organized APM program.

The application landscape is so crowded, companies just can’t seem to make sense of all the tools they have at their disposal. They struggle because the necessary data is so spread out across so many different applications, they can’t do the analysis to really understand what the actual condition of their assets really may be and how well they are really performing. It isn’t so much a lack of data, it's a lack of information.

Some of the problem is that the information is trapped in older equipment that doesn't have the ability to do anything other than display it locally. Sometimes the problem is that while you may be able to access the information electronically, the protocols are aged and proprietary. Another problem occurs when the information is accessible but the device has an antiquated OS that is no longer supported so security concerns keep you from accessing it.

Even if you can access all the information, there remains the challenge of ensuring the data is properly time-synchronized. Finally, add in the fact that many enterprises have multiple applications accessing the myriad of sensors and devices on the plant floor and often using the data in their own ways, trying to create a “big picture” so you can fully understand how each asset is performing becomes a daunting task.

In fact, in every practice area LNS Research is currently covering, the second greatest challenge to companies pursuing a particular performance improvement opportunity is “disparate XYZ systems and data sources.”

As we progress with our APM research we expect similar results to be reported by survey respondents. Upcoming research will address how to overcome this challenge when pursuing APM excellence.

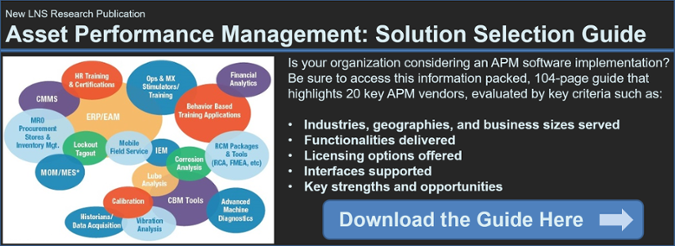

Understand the capabilities of twenty of the leading vendors in the APM space by downloading our APM Solutions Section Guide. The guide contains comparison charts for the factors listed above and the detailed profiles of the twenty vendors ranging from automation companies, to enterprise software providers and includes many specialized APM solutions as well.