With metals and other mining commodity prices near record lows, this century miners are focused on cost cutting and minimizing investments. Typically this cost cutting comes across the board impacting all areas--including maintenance expenditures, particularly for new technology.

During commodity lows, the pressure to reduce maintenance costs is often at its greatest with deferred maintenance being a typical way to put off spending precious expense dollars. Unfortunately this is the wrong behavior and advanced asset performance management (APM) practices offer their greatest benefit exactly at the time when margins are tight.

When money is readily available, you can assume a bit more risk since you can always throw dollars into resolving a crisis. But when times are tight, any unexpected expense can be catastrophic, and unexpected expenses are exactly what tend to occur when APM takes a back seat to production.

APM Reduces Risk

Advanced APM practices definitively help reduce risks in asset-intensive industries like mining. Both condition-based maintenance (CBM) and reliability-centered maintenance (RCM) are powerful tools when it comes to managing operational risk related to production asset performance.

RCM in particular embraces risk assessment as part of determining maintenance strategy for each asset. By performing a careful RCM analysis of critical assets, you actually determine the optimal level of maintenance to reduce failure as well as identify the profile of alternate actions and their associated costs. With this information in hand, miners can make intelligent decisions on how best to minimize maintenance costs.

CBM also can help reduce maintenance costs by guiding the timing of maintenance, avoiding over maintenance when not needed, and triggering maintenance sooner than might have been scheduled, ultimately avoiding expensive repairs from a more serious failure. Even switching to usage-based predictive maintenance (PdM) can help lower maintenance costs by avoiding performing unneeded maintenance on idle or lightly used assets.

The IoT Makes Enhanced APM More Affordable

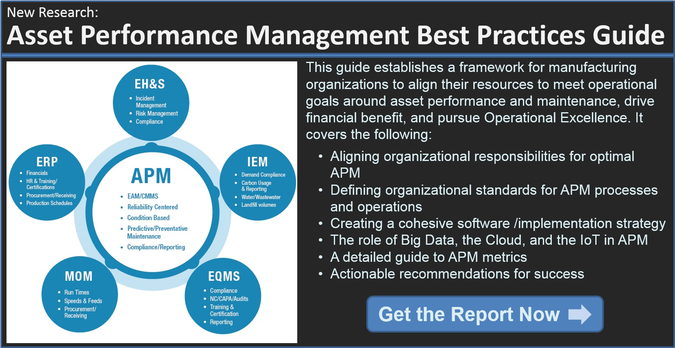

The Internet of Things (IoT) makes APM even more affordable in times like these. The incremental cost to instrument a critical asset is dropping rapidly thanks to the IoT. Add in mobility for instant access to the data smart connected devices are providing, and APM can make a huge difference in asset availability.

Instead of relying on generalities and teardowns, the data from smart connected devices allows for much more precise and focused service that not only increases asset availability but also reduces overall maintenance costs.

Cloud, Big Data and Social Media Also Enhance APM Effectiveness

The IoT is not the only new technology driving APM effectiveness. Social media is playing a role as well. The ability to join in communities of like-minded maintenance professionals both in the mining sector but also in other asset intensive industries, particularly those with common equipment, to solve maintenance issues and get advice can also help lower maintenance costs while increasing asset availability. Also by making use of the Cloud and Big Data, as it is applied by equipment OEMs, can also lead to enhanced APM performance.

So by leveraging the hot technologies available today and by emphasizing classic APM tools like usage-based PdM, CBM and RCM, APM practitioners can help miners significantly lower their production costs by increasing availability while lowering maintenance expenses and capital spends. While commodity prices are low, APM is the one area miners need to do more, not less to save money.