The Internet of Things (IoT) is being incorporated in an increasing number of industrial applications these days as IoT software application providers partner with larger platform providers, and the concerns that businesses have around things like security, implementation costs, and viability begin to slowly recede and be replaced with growing success stories that open industry's eyes to the vast potential for IoT technology within their respective organizations.

In this week's round up, we highlight some recent business activity from software and IT providers that's moving the IoT conversation forward, and take a look at some examples of how the IoT is already driving tremendous value in different industries through increased efficiency, improved safety, lower costs, and more informed decision making.

In this video, we see how Rockwell Automation is leveraging Microsoft's Azure IoT Services to create operational intelligence across the entire oil & gas supply chain, from extraction, transport, refining, all the way to the corner gas pump. At the Microsoft Convergence event last week, CEO Satya Nadella demonstrated how Rockwell is broadening its use of Microsoft's platforms to gain a broader data strategy, including managing enormous amounts of data on Hadoop, improved build planning and maintenance capabilities that work toward predictive analytics, and point-in-time restore capabilities for critical workloads, among others. Jeff Wettlaufer, Senior Technical Product Marketing Manager at Microsoft IoT, recounts the event the Microsoft blog.

http://blogs.cisco.com/ioe/goldcorp-raises-the-bar-and-builds-the-mine-of-the-future

From oil & gas production to mining, IoT is already showing tremendous potential and payoff. With virtually every piece of equipment now connected via IoT technology, Goldcorp, a gold producer based in Vancouver, British Columbia, has armed the workforce in its Quebec mine location with real-time or near real-time information, some of which used to take as long as a month to recover. Incorporating Cisco's Connected Mining Solution, Goldcorp's incredible acceleration of information flow has resulted in many benefits, including improved safety of workers underground. With IoT-enabled operational intelligence, Goldcorp is able to pinpoint exactly when and where ventilation needs to be pumped underground, and has allowed the company to reduce its usage of air by almost half--from 1.2 million cubic feet per minute to 650,000 cubic feet per minute. Each human and piece of equipment is tagged with an RFID locator, so if a vehicle engine is started, this additional carbon monoxide is automatically accounted for and offset by increased ventilation through the ventilation on demand system. Douglas Bellin and Patrick Gilbert have the full story at the Cisco blog.

SAP announced this week that it was entering into an IoT implementation project with GEA, a supplier to the food processing industry, to improve the company's condition monitoring and predictive maintenance capabilities. Based on the SAP HANA Cloud Platform, the project aims to reduce structural complexity and accelerate operational excellence while recuding costs and fostering growth. Specifically, technicians will be able to remotely monitor equipment, and identify unusual trends in real time. The solution will also integrate with other software applications from SAP already in place, and leverage cloud technology. Speaking about the partnership, GEA CEO Juerg Oleas said, "We at GEA aim at strengthening and ruther developing our oustanding market position through continuous innovation...With this cooperation and the new SAP solution, we are enhancing the processes of our customers to a new level of efficienty. Full press release...

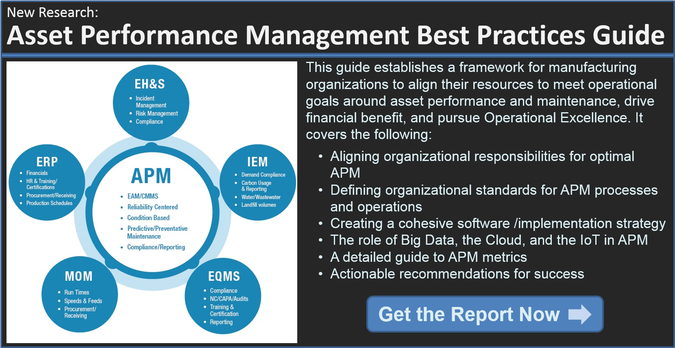

Expanding on the petro/mining theme, LNS principal analyst Dan Miklovic had a great post earlier this week that discussed some less tangible benefits of Asset Performance Management (APM), that while hard to attach a particular price tag, are crucially important. If perception is reality, as is so true in many cases, than perception management requires the same level of care and attention as the realities on the ground. Regardless of which party within the supply chain may actually be at fault in a mining or petrochemical disaster that results in deaths or environmental damage, the company that most stands to profit will almost always be seen as guilty in the court of public opinion. On top of the numerous operational benefits that actually lessen the likelihood of an event, which is rightly what may be the main focus of an APM investment, Dan's advocacy of APM as a reputation management tool is an interesting one, and one that mining/petrochem companies are beginning to understand they need to extend to their suppliers and partners as well. Full post...