Recently, when gasoline was available in some places in the U.S. for under $2/gallon most people were enjoying the extra money in the economy and the petroleum industry didn't capture very many headlines. Now that gasoline is headed back to $5/gallon in some places, like California, the industry is once again in the news, and usually not in a favorable light.

Several things have led to the recent spate of news reports about the industry. First of all there is the strike that has affected production; then the California refinery accident that reduced refining capacity for the state, and is impacting the West; and finally, transportation issues and accidents that really don’t impact prices much but certainly don’t help the industry's image with the public. The petroleum industry needs to take a step back and focus on Asset Performance Management (APM) to address not only its operational issues, but also buoy its public image. Below, I'll discuss why APM is a critical tool.

APM, Performed Well, Reduces Accidents Across the Supply Chain

Whether at the well-head, the refinery, or any part of the transportation train failures that result in any kind of accident result in economic impact and reuptation damage. This is particularly true of incidents with Environment, Health & Safety (EHS) implications. APM is one of the most recognized tools to reduce Operational Risk Management (ORM) from accidents. As we have reiterated numerous times in the last year: “Healthy assets are the foundation of a healthy business.” Worn out and improperly maintained equipment ranks right next to human error as the leading cause of accidents, and all but invites that outcome. A simple analogy any motorist can relate to: If you don’t maintain the brakes on your car eventually you won’t be able to stop when you need to and an accident is bound to occur. The same is true on a crude train or finished goods tanker. And whether the petroleum company owns the transportation asset or not the fact is that the public still sees the industry as the offending party, and its reputation still suffers with every accident.

When it comes to wells, either on land or offshore, the damage from accidents is directly linked to the producer, and likewise at the refinery. In both transportation and production cases the loss of production volume still impacts the bottom line. With reduced capacity, prices invariably increase and this further erodes the public's trust in the petroleum industry. Every accident that APM could have prevented results in a two- to three-fold impact on the company's bottom line. With those stakes, APM seems like a pretty good investment.

Right now one of the major factors impacting oil production and supply, and supposedly increasing prices as well, is capacity restriction due to labor situations across the U.S. Regardless of whether a labor action is “right or wrong,” or which side you take, there is a link to APM and production capacity. A well-maintained facility is much easier to operate and more likely to maintain production volumes, even if short-staffed. Also, if the production facility is kept at top operating efficiency and condition at all times, forced maintenance delays that might occur during a labor dispute, or even other potential situations like supply chain disruptions caused by natural events (e.g. weather) allow for longer sustained peak-level performance than a facility that is always on the verge of failure.

In this scenario APM plays a role that enhances a company's ability to keep its assets performing at or near peak levels. Through the use of enhanced sensing, broader data collection, and better data analytics an operator simply better understands the plants condition and, more importantly, if applying reliability centered maintenance (RCM), the ORM implications of his or her maintenance activities. Even when RCM is not utilized, just the better overall condition resulting from better and timelier maintenance yields significant payback.

So while supply and demand and crude prices may be swinging widely these days, the smart producers are not only applying APM to their own operations, but insisting their transportation partners do so as well. These are the companies that don't make the news, which is good for all involved.

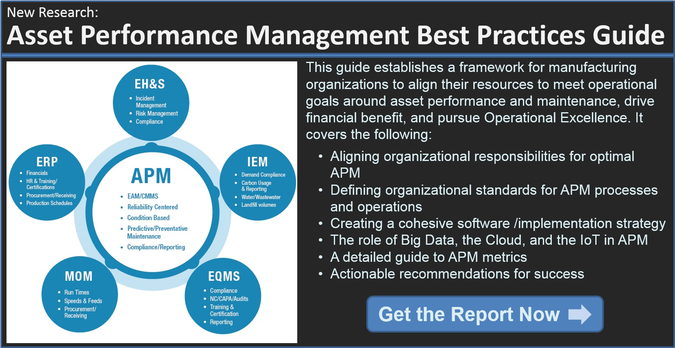

APM Best Practices Guide

Over the past several decades, APM has grown significantly in scope through new standards, software technologies, strategies, and integrations with other key business areas. Today, it is an essential component of achieving Operational Excellence. But, because the stakes have risen and the breadth widened, it's difficult to know where to begin (or augment) your APM strategy. The APM Best Practices Guide provides APM professionals with a comprehensive framework to align their people, processes, and technology for sustained success.