The Lean Certification Alliance has recently introduced new improvements to the Lean Certification program that are driven by customer feedback. Candidates for Lean certification now no longer pursue and achieve the hierarchical Bronze, Silver, and Gold sequence, so that candidates can achieve certification at a rank that is most appropriate for their career, knowledge, and experience.

Jeannine Kunz, Managing Director, Workforce and Education at SME, said "Technology is changing so rapidly these days and the manufacturing industry continues to evolve and develop at high speed, which means the workforce needs to keep up. The changes were introduced after an extensive market study based on the Plan-Do-Check-Act cycle and listening to customer feedback, and implemented by the four non-profit organizations involved: ASQ, AME, the Shingo Institute, and SME. More...

Streamlining Manufacturing Productivity with Mobile Capabilities

Over at the Dassault blog, an interesting infographic on mobility in manufacturing was posted recently, illustrating the interconnected benefits mobility is providing in acclerating Operational Excellence and streamlining operations, from plant communications, asset maintenance, quality control, field service, management, and more.

Among the market predictions put forth by the infographic are a 33% expected growth in mobile enabled manufacturing through 2017, and that 23% of of all mobile enterprise services will be made up by the manufacturing sector by next year. View the infographic here.

A number of our team members are in Hanover, Germany this week, and there have already been some interesting announcements of collaborative events. Fujitsu, a Japanese information and communication technology provider in over 100 countries, has partnered with Microsoft to accelerate Internet of Things (IoT) technology. Combining Windows 8.1 Pro and Fujitsu's Cloud A5 for Microsoft Azure and M2M platform, the two companies have partnered to optimize processing by both machines and humans. Fujitsu brought together its Eco-Management Dashboard, The IoT/M2M platform, Microsoft cloud services, and Windows tablets to enable managers, engineers, and scientists to improve product quality, streamline systems, and enhance functionality while reducing costs.

In this solution, scattered data is input into the Microsoft Azure database and evaluated through advanced analytics and natural user interfaces. The dashboard is then used to simultaneously manage product quality, process efficiency, and equipment performance to improve operationa and reduce energy costs.

"We are proud to partner with Fujitsu to enable the next generation of manufacturing business models and services enabled by IoT along with advanced analytics capabilities like machine learning," said Sanjay Ravi, managing director, Discrete Manufacturing Industry at Microsoft. Full press release...

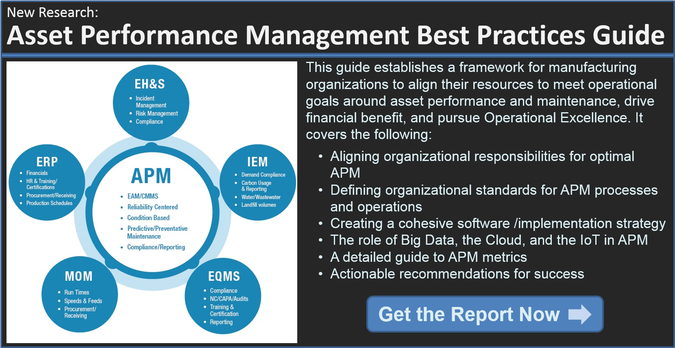

By now, many industrial organizations have begun to realize both how broad the scope of Asset Performance Management (APM) is, and how important it can be to improving operations, maintaining quality standards, and boosting the bottom line. But as with other pillars of Operational Excellence, an effective APM program is about more than just technology or svelte processes; it's about the optimal alignment of people, processes, and technology across the discipline. In a post earlier this week Dan Miklovic discusses where the bulk of APM efforts lie, how to make sure culture and processes mesh appropriately, and how choose the right path for your organization when pursuing APM technology. More...