It seems everyone in business these days is obsessed with driving productivity or quality improvements, or talking about driving costs down or improving sustainability. Why then do so many still treat plant (or asset) maintenance like “that cousin we don’t talk about?"

Enterprise maintenance activities generally remind us of how we approach maintenance in our own lives–that is, when something breaks we fix it, and generally it breaks at the most inopportune time, like getting a flat on the way to dinner.

So maybe it’s no wonder businesses tend to think of asset maintenance as a cost of doing business that we need to minimize, thinking that in doing so it means we don’t have problems. Unfortunately, asset maintenance and asset management are not the same thing, and while we should be managing our assets, too often we just maintain them, and then rather poorly.

So maybe it’s no wonder businesses tend to think of asset maintenance as a cost of doing business that we need to minimize, thinking that in doing so it means we don’t have problems. Unfortunately, asset maintenance and asset management are not the same thing, and while we should be managing our assets, too often we just maintain them, and then rather poorly.

Currently roughly 3 out of 4 plants in the world still practice reactive maintenance as the norm. In fact when surveyed, contributors to LNS Research’s recent studies show that among all the applications typically used to support business, asset health management ranks lower than most with only 38% adoption.

Just as maintaining a physical asset itself is difficult without the proper tools, maintaining the overall portfolio is difficult without the proper tools—in this case asset health and performance management software.

Unhealthy Assets Equal Poor Business Performance

It almost seems intuitive that poor health leads to poor performance, since we all recognize that we as individuals cannot deliver our best efforts when we’re not healthy. Manufacturing plants are no different.

When production equipment is poorly maintained it generally can’t maintain the tolerances required to achieve quality targets. If it is unhealthy, it’s likely suffering excessive downtime. Both of these lead to much lower OEE, since OEE is a product of availability, quality, and production volume.

Likewise when an asset is poorly maintained it also consumes excessive energy and can even present a safety hazard. Think of your own car–according to the EPA the number one contributor to poor fuel economy as a whole is improperly inflated tires, usually underinflated tires. Underinflated tires, if severely underinflated, can also cause handling issues potentially leading to an accident.

If we take that analogy to the industrial workplace think about the mine haul truck with underinflated tires (each of which can cost upwards of $10,000). Not only is fuel economy and safety critical, but hauling capacity is what defines productivity.

Why do manufacturers struggle with Asset Management?

Besides lacking the proper tools as discussed above, the other major reason businesses struggle is in adequately quantifying the benefits of specific maintenance projects. Use Google to search “benefits of predictive maintenance” and you'll find dozens of articles on the areas where you can accrue benefits, but very little on the quantitative size of those benefits.

The reason quantification is so difficult is that the available gains are dependent on your baseline. As with most other process improvement projects the Pareto principle holds. If you are already doing average or better incremental improvement is significantly harder than if you are among the poorest performers.

Similarly the benefit of a specific technology will vary by the use-case. Vibration monitoring in a high-speed turbine could prevent a significant failure cost but vibration monitoring of a low-speed conveyor belt (not its bearings but the belt itself) may not provide any valuable insight in some cases such as conveying crushed rock in a quarry.

Asset Health and Performance improvement is difficult without adequate investment and getting the necessary funds to invest in the technology needed to accomplish your goals is a prerequisite.

Justifying Asset Health Investment

LNS Research’s Energy and Asset Management practice has identified this as a key research topic going forward. Expect to see more blog posts on the topic as well as research in the future on the entire asset management area.

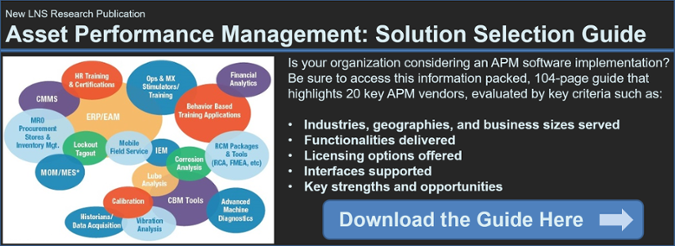

Understand the capabilities of twenty of the leading vendors in the APM space by downloading our APM Solutions Section Guide. The guide contains comparison charts for the factors listed above and the detailed profiles of the twenty vendors ranging from automation companies, to enterprise software providers and includes many specialized APM solutions as well.