In a recent post, we asked which term manufacturers are using to describe the practice area as well as solutions for managing the physical assets they use to manufacture their products. While the response level is still low there seems to be a split between Enterprise Asset Management (EAM) and Asset Performance Management (APM). This is from a fairly large field of candidates:

(Take the survey at the bottom of this post)

The Problem with Three Letter Acronyms (TLAs)

With the exception of CMMS, all of the above are TLAs, which seem to dominate IT and manufacturing these days. See ERP, MOM/MES, and EHS for reference. The tendency to rely on TLAs probably stems for our desire to be efficient. It’s so much easier to say “EAM” than “Enterprise Asset Management.”

The competition to create new acronyms springs partly from the solutions provider community that is continuously trying to differentiate itself from its competitors. Part of it comes from the need to differentiate evolving functionality as suppliers enhance their products.

I introduced the term EAM to the marketplace nearly 15 years ago as a way to differentiate integrated products that combined financials, inventory management, HR and procurement from the basic work scheduling and tracking features that existed in CMMS offerings in the 1990s.

Originally EAM was meant to be the parallel in asset-intensive industries to ERP in classic manufacturing. Over the last 15 years, EAM has taken on a life of its own and if you ask five different people what EAM is you’ll get at least 5 or more answers.

This certainly complicates life for the buyers of technology. Not only do they have to decide what type of solution they want, EAM, CMMS, APM, and so on, but then they must evaluate each solution provider’s claims against their own needs.

Unfortunately, acronyms are here to stay and despite their shortcomings we have to make the best of them.

APM – LNS’ Choice to Describe Plant or Production Asset Optimization & Management

Based on the feedback from our survey and the need to expand the scope of what we believe world-class manufacturers need to do to maintain an optimally performing plant, we are adopting the term Asset Performance Management as the label for the practice of maintaining and operating the physical assets of a facility in a way that optimizes their performance.

We believe the term APM is inclusive of and leverages the collection of CMMS, EAM, CBM, RCM, and all the other tools such as predictive and preventative maintenance. The idea is that assets need to be managed with the appropriate tools and in a way that recognizes their contribution to the overall performance of the manufacturing enterprise.

As noted in my earlier blog post, asset performance impacts quality, production rates and efficiency, energy consumption, safety, environmental performance and just about every other aspect of operating a manufacturing facility. When viewed from the asset-centric perspective, business functions and practice areas that are all impacted by APM tend to include:

- Industrial Energy Management

- Manufacturing Operations Management

- Environment, Health, & Safety

- Enterprise Quality Management

- Enterprise Resource Planning

While other terms such as asset health management and asset performance optimization also reflect the scope, the consensus among LNS blog readers that APM is a useful term leads us in that direction.

The most important thing is that whatever term your firm uses to describe the care of your production assets, that you clearly define the activities that contribute to extracting the most performance from those assets and you select the appropriate tools to accomplish your goals.

Forthcoming research will explore the APM landscape, its benefits, and APM's impact on OEE, IEM and EH&S specifically.

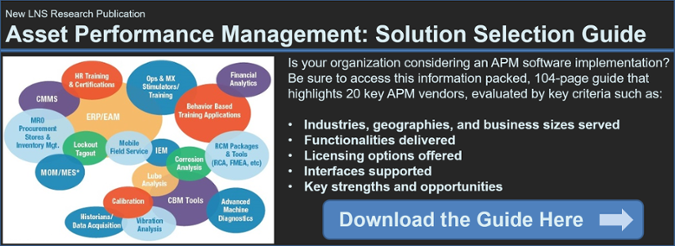

Understand the capabilities of twenty of the leading vendors in the APM space by downloading our APM Solutions Section Guide. The guide contains comparison charts for the factors listed above and the detailed profiles of the twenty vendors ranging from automation companies, to enterprise software providers and includes many specialized APM solutions as well.