At LNS Research, we fully endorse social media and understand the importance of being a good “netizen.” We regularly blog, tweet, start discussions on LinkedIn and Google+, and we make sure we’re interacting with and learning from others through those mediums.

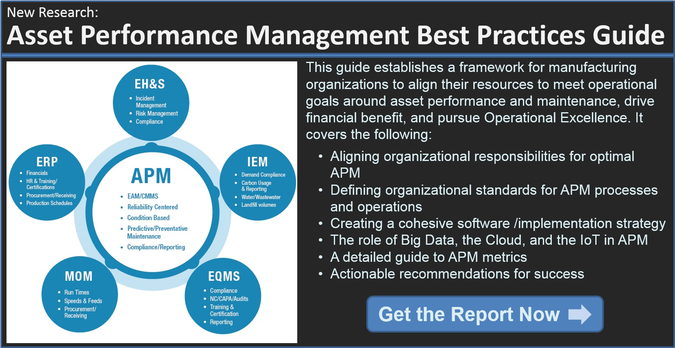

In the asset performance management (APM) space, being a good netizen applies here, too. And it could pay off big time, as the IoT becomes more prominent and the amount of asset performance data continues to grow.

Netizenship in the IoT future will mean more than engaging in social media—it will mean sharing the rich data that enterprises will collect from all of their M2M connected smart devices.

What Types of IoT Data Will Good Netizens Share?

We have blogged extensively on how the IoT is going to transform the APM space as well as Manufacturing Operations, Environmental, Health & Safety and the Energy Management spaces. We have also cautioned on some of the risks of data sharing.

Overall, we believe the good outweighs the risk. In previous postings we have talked about how the IoT would allow for new business value to be created as OEMs and service providers aggregate equipment performance data.

By sharing data about equipment performance, downtime, and process parameters, enterprises will get direct value in that they should be able to both better predict remaining service life of plant equipment as well as gauge as to how particular pieces of equipment are performing in contrast to a larger sample of similar equipment.

For the majority of enterprises this will mean enhanced reliability due to improved condition-based maintenance (CBM).

Going Beyond Condition-Based Maintenance

There is more value to be gained, though, by sharing more information.

If you share another level of detail about your processes, such as the actual environment, materials being processed, and even detailed equipment specifications along with more detailed information on failures when they do occur, an aggregating service provider could use that information to provide an order of magnitude greater value.

Obviously security and protection of proprietary information is a major concern in such a scenario, but assuming those obstacles can be overcome, the value could be significant.

Envision the ability to ascertain what brand and model of a piece of equipment would offer the lowest lifecycle total cost of ownership in specific process train manufacturing specific product sets. Then imagine being able to determine once you used that equipment if the performance you achieved was comparable to others using the same equipment in similar process manufacturing similar products.

Achieving operational excellence takes on a whole new meaning in this scenario.

Why Benchmarking Makes Sense

As we posted early this year, the majority of companies are either currently benchmarking themselves against the competition, plan to do so, or have done so in the past.

By being good APM netizens, they have the potential to expand the scope of what they can benchmark. The potential is pretty much unlimited.

We recently saw a demo of this capability by Meridium, where its Asset Answers solution has the capability to show not only how a company is performing compared to the industry, its peers, or even within its own walls on a unit-to-unit basis, but down to the equipment level on a manufacturer-by-manufacturer basis specific to a particular process as well.

The potential payoff of access to data which can facilitate plant optimization at procurement or replacement time for lowest lifecycle total cost of ownership is pretty powerful. Start thinking now about how you will improve your APM netizenship.