It’s not uncommon today, if you visit a manufacturing plant, to see large digital displays peering down at the workforce, keeping everyone apprised of some of the key metrics, measurements, and statistics of what’s happening on the shop floor. Listed among these backlit harbingers, you might see a board with three ominous vowels—“O,” “E,” “E,” Overall Equipment Effectiveness. Surely this metric holds great importance to all beneath its glow.

And indeed, OEE can be a valuable and important metric, if applied correctly. But as we’ve discussed in previous posts, it’s a metric that’s often misused, sometimes in the way it is interpreted, and sometimes with the amount of influence it’s allowed. In this post, we’ll look at six misconceptions about OEE and the way it can be used.

1. OEE should be used by executives as a holistic business measurement

Originally, OEE was designed as a single machine performance calculation within a lean manufacturing construct. The goal was to understand how a particular machine was performing over a period of time to measure progress. The tendency to aggregate OEE by plant or line of business or at a higher level was not the original intent. And, depending on the scale and type of your operation, diversity in asset number and makeup, this larger aggregate number can have a wide variance in the truth it provides. In most cases, it is best to avoid this approach.

Tweet this myth!

2. Everything needed to calculate OEE comes in a single MOM or MI solution

Typically, almost all of today’s Manufacturing Operations Management (MOM) or Manufacturing Intelligence (MI) applications have the capability to measure two out of the three inputs needed to calculate OEE: Production and Quality. Machine availability is usually more difficult to obtain, and often requires integration with a CMMS or Enterprise Asset Management (EAM) System to obtain this maintenance-related data.

When the maintenance functionality is offered by a MOM or MI solution it generally is only suitable as a maintenance system for a light manufacturing situation. For asset intensive industries like mining, oil & gas, metals, and others, a more robust system architecture would typically be necessary for maintenance, so the MOM or MI solutions in those industries do not have full OEE data collection capabilities.

Tweet this myth!

3. Applications specifically made for calculating OEE are as easy as “plug and play”

Many solutions marketed as OEE point solutions are dashboarding systems that assume you already have the data sources to accurately calculate OEE to begin with. The calculation itself is simple. The real challenge is to have these data sources and analytics present in the first place for the three determinants of OEE.

Tweet this myth!

4. OEE is an equalizer between machine centers, processes, and other operational areas

As we’ve touched upon before, you can’t compare machinery and assets that have vastly different functions. The OEE achievable on each is highly dependent on the nature of the asset and its function within the manufacturing process.

Tweet this myth!

5. Direct insights can be gleaned from looking at the final OEE number

It’s tempting to look at your overall OEE value and make a quick comparison to what is often talked about in the marketplace (85% being “market leading,” for example), but the overall number tells little about how the asset is operating. You must look deeper into the three values inputted to reach this number to really understand what’s happening with your performance and understand the real successes and/or areas for improvement.

Tweet this myth!

6. OEE is a direct indication of profitability

There is no financial element in an OEE calculation, and it has very little connection to business value. It doesn't factor the cost of materials, cost of labor, importance of customer, price paid by customer, or even if a customer order exists. Therefore, maximizing the OEE of an asset is not the same as maximizing the profitability of an asset.

Indeed, it's possible to have very low OEE for a particular machine center but if the part being made is a critical, low-volume/high-value part it may be highly profitable. On the flip side, you can have extremely high OEE but if material costs exceed the finished good market price you will never be profitable. In fact, the more you make of such an item the more unprofitable you may be. However, if you achieve an OEE number of X and improve it by a certain percentage, chances are you will see some corresponding improvement in profitability. While a direct link is lacking, there CAN be some correlation.

Tweet this myth!

Should You Calculate OEE at All?

Despite some of the shortcomings described above, OEE does serve an important role in benchmarking your performance and understanding where the most “bang for the buck” can be achieved in improving production capabilities. As alluded to in the previous post, OEE is an excellent way to measure the effectiveness of individual machine assets, or groups of identical assets performing a similar function and can be a valuable tool in sustaining continuous improvement efforts.

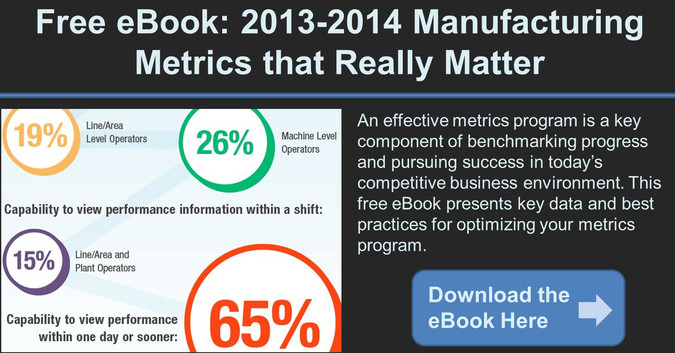

For more information on the metrics driving the most value for manufacturers today, read our eBook, "2013-2014 Manufacturing Metrics that Really Matter," based on research conducted between LNS Research and MESA International.