Wearable technologies may be a hot topic right now, but they've been around and evolving for quite some time. Google Glass has been used in plant asset maintenance for a couple of years now. And early adopters have used tools like Innovega or MicroOptical to display service instructions and illustrated parts breakdowns (IPBs) to service technicians for more than a dozen years already. These heads-up display technologies (HUDs) allow technicians to readily access repair information in the field while servicing equipment, shortening downtime and increasing the effectiveness of repair activities.

RFID has also been used to track maintenance personnel, particularly in hazardous locations, sometimes even engaging interlocks to ensure safety of workers, and not just for tracking and reporting. In highly dispersed operations like mining or oil field services, wearable GPS has also been leveraged to improve the safety and productivity of asset care staff.

So with wearable technology already present in the APM space, what is going to create the next step-change that will drive wearable from a tool that is useful but only moderately deployed to a must-have technology? Two factors are at work: one is the consumerization of the technology and the other, perhaps larger influence, is the Internet of Things (IoT).

Consumerization Will Lead to Cost Reductions

When MicroOptical introduced its HUD glasses in the early 2000s, the price then was roughly $2,000 or about $2,500 in today’s dollars for a device that simply was a VGA display. Compare that to $1,500 for Google Glass today, which offers so much more, including high definition display, an integrated 5 MP camera, full audio, and a wireless connection.

There is no denying that the power of consumerization has continually driven the cost of technology down and led to the wide adoption of consumer technology in the manufacturing sector. Starting with the displacement of proprietary display and PLC programming with PCs in the early 1980s, the migration of consumer technology onto the manufacturing floor resulted in productivity improvements and better decision-making.

Wearable technology will not be an exception. Even if nothing else changed, the lowering of the cost of wearable technology would make it more prevalent throughout the plant, including the APM space. But an inflection point is on the horizon. There has been much written about how the IoT will transform manufacturing. The biggest question often surrounding the IoT in manufacturing, however, is where is the value proposition?

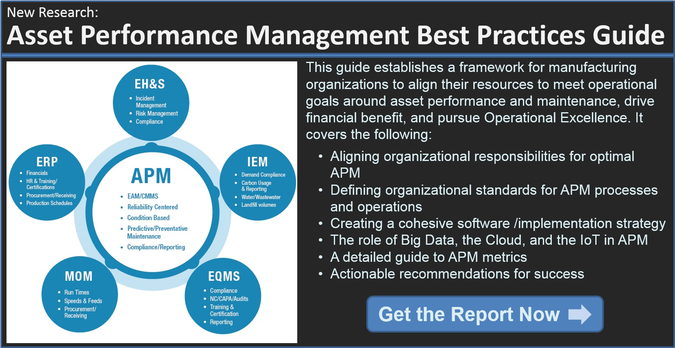

The one area that consistently is mentioned as the exception and is already delivering value from the IoT is APM. Using additional information from the process equipment, leveraging the IoT to better forecast failures and consequentially schedule preventative maintenance activities has produced documented downtime reductions and maintenance cost savings.

The IoT Changes the Game in Asset Performance Management

What the IoT, coupled with wearable technology, will deliver is a new capability that has not yet been exploited. To date, the IoT has provided just additional data, which has improved the ability to predict failure and trigger maintenance activity.

Wearable technology has only delivered the technician the details of how the device might be repaired using step-by-step workflow/guidance. This results in a situation where we know what might fail and how to fix it once it does or what to do to potentially preclude the failure. What has been lacking is a deep understanding of why and how failure occurs.

The practice of Reliability Centered Maintenance (RCM) has focused on trying to answer these questions using tools like FMEA (Failure Mode Effects Analysis) in an off-line mode. Imagine the power of RCM specialists being able to access a complete operational profile of equipment, in the field, as they are servicing it. The ability to actually see an animation of the equipment performance changes leading up to the current situation will provide better insight as to what actions to take to preclude future failures. This is but one example of how the combination of the IoT and wearable technology will likely transform APM.

As my colleague Paul Leavoy noted in his blog post on wearable technology and EHS, safety is another area where wearable technology will have a big impact. As operator and maintenance tech roles merge in some industries, the benefits of having more information readily at hand will transform the value we can extract from our manufacturing assets.

LNS Research will be ramping up its APM research practice in the next few months, but in the meantime we invite EHS leaders to participate in our new survey and read the EHS Best Practices Guide.